|

|||

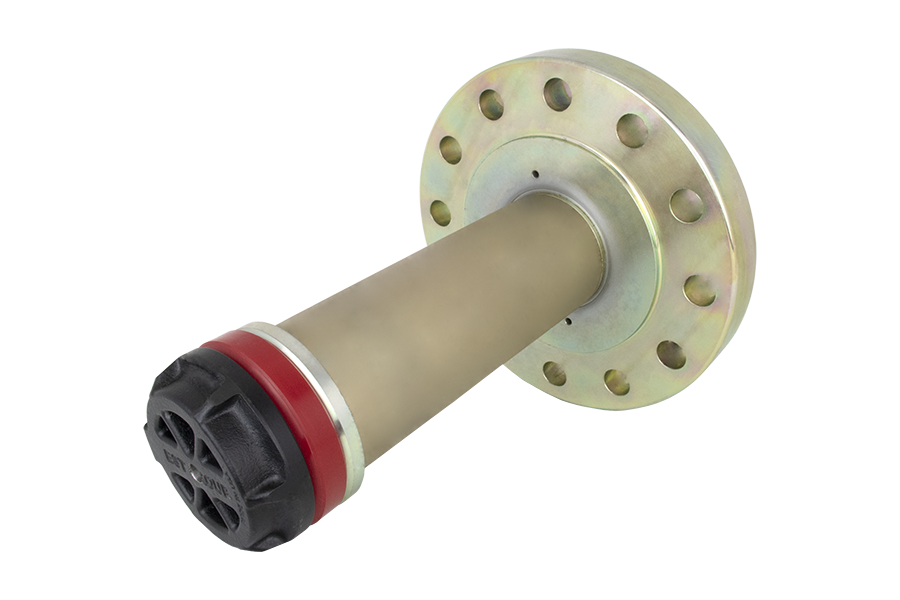

High Lift Flange Weld Test Plug |

|||

Monitor upstream conditions, isolate and purge the weld area, perform the weld, and hydro test the weld joint with one easy tool. No blind flanging upstream, no vacuum truck for evacuating the line, and no X-raying. Each test requires a minimum amount of water, no need to fill the entire line. You will use less water and minimize your environmental impact. Operating pressures to ANSI B16.5 requirements. |

|

||

Test Pressure Size Range Standard Seal Material Features • Designed to function in four distinct ways: as a purge dam, weld fixture, test plug, and a weld isolation plug • ASME PCC-2 Type III testing device1 |

|||

| Literature Sheet | |||

| Operating Procedures: 3/4" - 8" (DN20 - DN200) |

|||

| Operating Procedures: 10" - 24" (DN250 - DN600) |

|||

| Operating Procedures: 6" - 24" (DN150 - DN600) |

|||

| Operating Procedures: 3/4" - 4" (DN10 - DN100) |

|||

| Operating Procedures: Isolation Plug without Flange |

|||

| Technical Specifications | |||

| HL2 Technical Specifications | |||

To Contact Your Local Sales Office Click Here |

|||

*Higher pressures available upon request.**Alternative seal materials are available including Neoprene, Fluoroelastomer, Silicone, EPDM, Natural Rubber, Nitrile Buna-N, and SBR Buna-S. |

|||