|

||

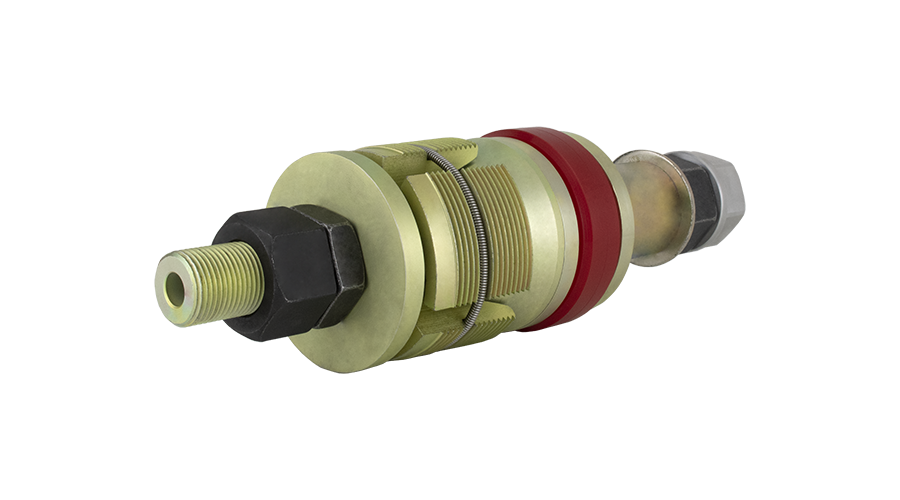

GripTight® Reverse Pressure Test Plug |

||

Pressure test flange-to-pipe welds with full radial, hoop and axial stresses – equivalent to the stresses that would be produced when using a blind to pressurize the entire piping system. Pressure testing can effectively verify the weld integrity providing the user confidence that the flange and weld will properly function when placed into service. |

|

|

Test Pressure Standard Seal Material Features • Subjects the flange-to-pipe weld to full radial, hoop and axial stresses during hydrostatic testing • Flange-to-pipe welds can be tested without needing to pressurize the entire system • Optional lanyard assembly acts as visual plug movement indicator allowing the operator to monitor the plug position during testing and halt work if improper installation occurred • ASME PCC-2 Type IV testing device1 |

||

Literature |

||

Operating Procedures: |

||

Operating Procedures: |

||

Operating Procedures: |

||

| Technical Specifications | ||

To Contact Your Local Sales Office Click Here |

||

Higher pressures available upon request. **Alternative seal materials are available including Neoprene, Fluoroelastomer, Silicone, EPDM, Natural Rubber, Nitrile Buna-N, and SBR Buna-S. |

||